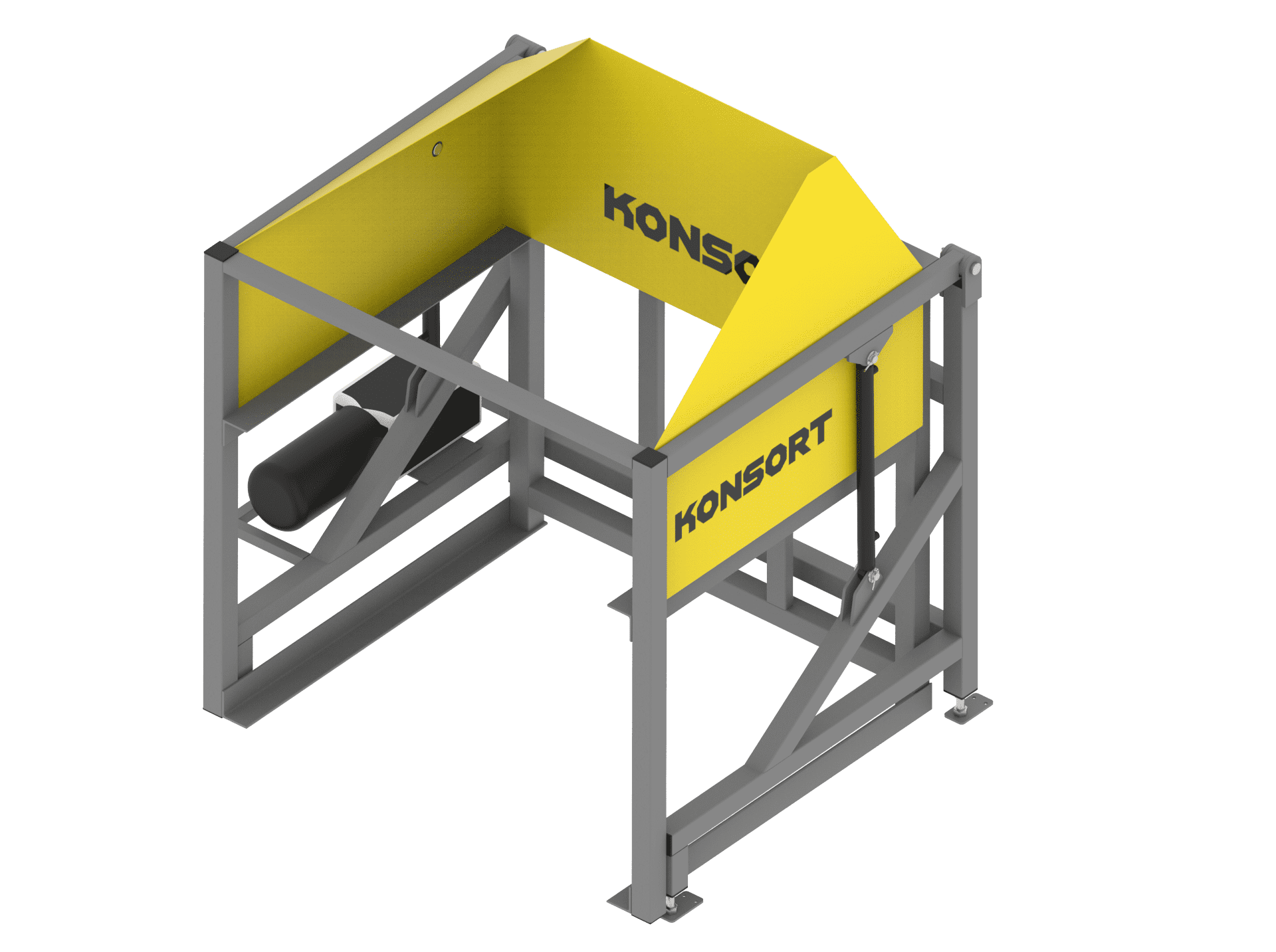

Container tipper

The container tipper is an industrial device designed for automated lifting and tilting of heavy containers, bins, crates, and other vessels. Modern enterprises rely on automation to optimize logistics and production. KONSORT equipment significantly reduces manual labor, increases processing speed, and minimizes the risk of workplace injuries.

Key Advantages

✅ Durable construction

The metal frame is made of high-quality steel with anti-corrosion protection. An optional version made from AISI 304 stainless steel is available — ideal for food production facilities.

✅ High performance and efficiency

This equipment enables fast processing of large quantities with minimal time and labor input. It is an essential solution for companies focused on productivity and safety.

✅ Automated control system

User-friendly interface and full compatibility with industrial automation systems make it easy to integrate into existing production lines.

✅ Gentle tipping

The tipper ensures careful container handling without damaging the contents.

✅ Versatile configuration

Adaptable for containers of various sizes, weights, and shapes — from standard plastic crates to custom containers.

Why choose a container tipper from KONSORT?

KONSORT is a Ukrainian manufacturer with extensive experience in industrial automation. We offer not only quality equipment, but also personalized engineering support for each customer.

- The container tipper price is competitive and depends on configuration. We deliver cost-effective solutions directly from the manufacturer — no intermediaries.

- Order your container tipper in Ukraine via our website or by phone — our team will help select the optimal solution.

- Custom builds are available based on specific production requirements.

- Full service support: consultation, installation, commissioning, and staff training.

Order your container tipper from KONSORT today — and automate your workflow efficiently!

High-quality organization of the production process (management process)

High-quality organization of the production process (management process)  Productivity increase up to 70%

Productivity increase up to 70%  Workforce optimization

Workforce optimization  Reduction in human-related risks

Reduction in human-related risks - Product feeding for loading or further processing

- Food industry — for tipping raw materials in bags, containers, or tanks.

- Agro-industrial sector — for handling feed, grains, and seeds.

- Warehouses and logistics — automation of loading/unloading processes.

- Processing facilities — integration into supply and processing lines.

- Meat and dairy industry — where hygienic and precise ingredient handling is required.

- European design

- Manufacturing process automation

- Various side board options