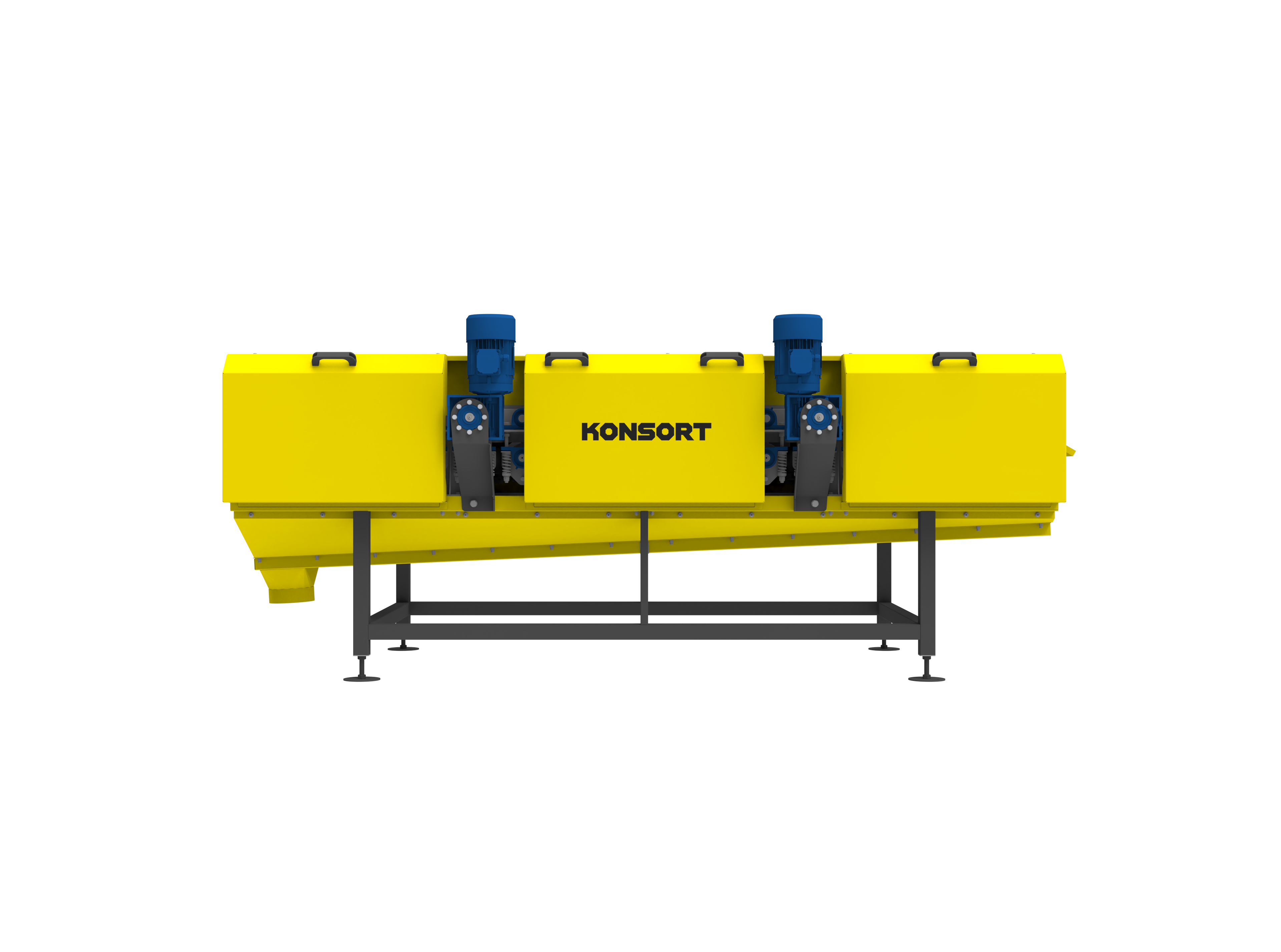

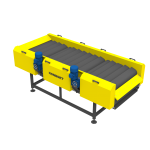

Drying machine with felt rollers (conveyor)

Felt roller drying machine (conveyor) — an efficient solution for automating the drying process of berries, fruits, and vegetables

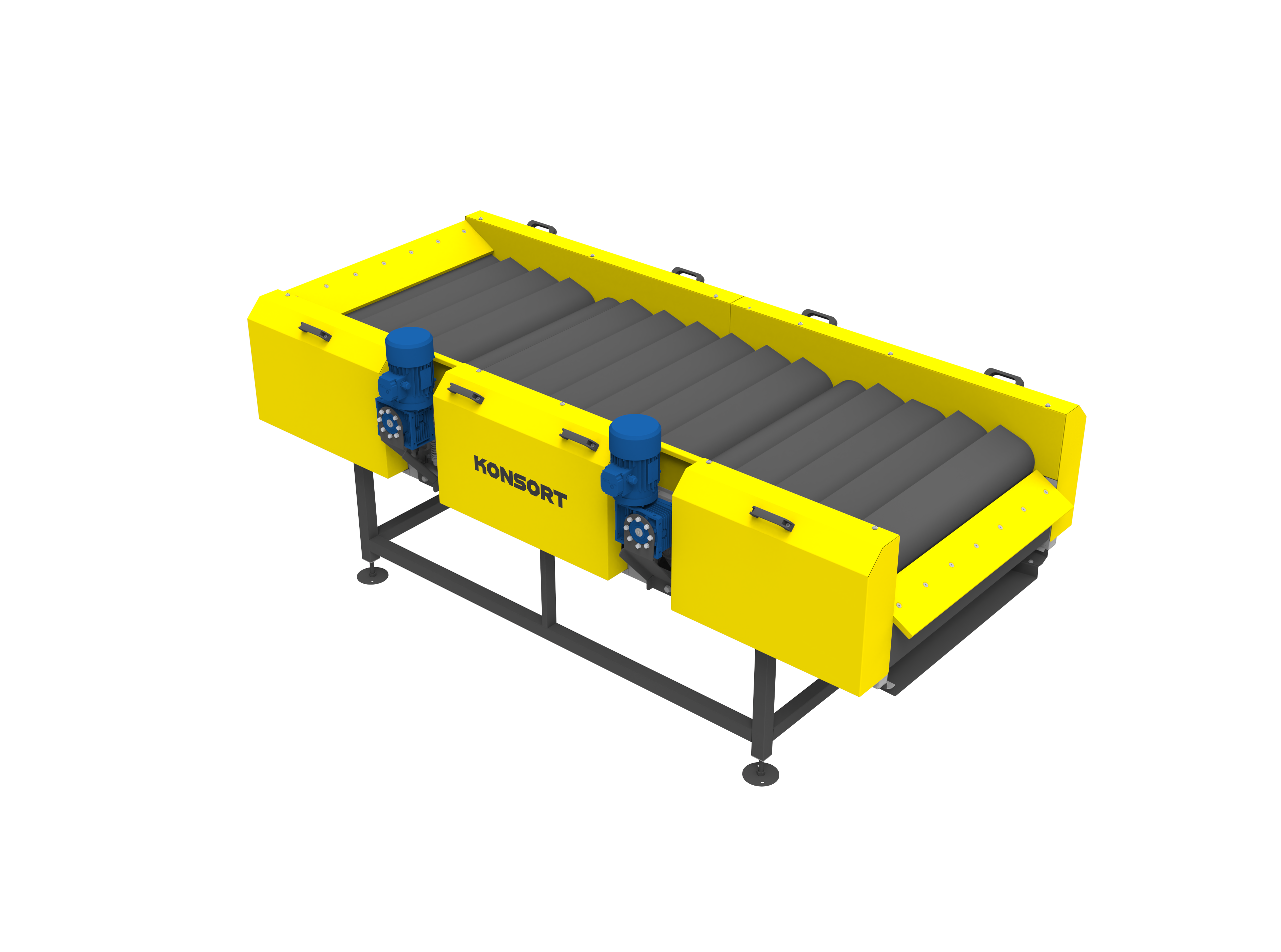

The felt roller drying machine from KONSORT is a reliable conveyor-based system designed to ensure fast and gentle removal of residual moisture from the surface of products after washing. Thanks to its high-density felt rollers, the machine is ideal for handling berries, fruits, and vegetables while preserving their integrity and commercial appearance. It is widely used in production environments where high throughput and delicate treatment are essential.

Key Advantages of KONSORT Equipment

✅ Gentle drying of products without damaging the structure of fruits or vegetables

✅ Felt rollers with high absorbency, effectively removing surface moisture

✅ Adjustable conveyor speed for optimal adaptation to various product types

✅ AISI 304 stainless steel construction — hygiene, durability, and food safety

✅ Integration-ready design — easily incorporated into existing automated processing lines

Who should use a felt roller drying machine?

This solution is ideal for:

- Processing facilities producing berry, fruit, and vegetable products

- Companies involved in freezing or packaging of fresh produce

- Agro-processing plants and food production enterprises

- Storage and logistics centers requiring preparation of products for cold storage or shipment

Why Buy a Felt Roller Drying Conveyor from KONSORT?

- In-house manufacturing in Ukraine — direct quality assurance from the manufacturer, no dealer markups

- Complete customization and configuration tailored to your production process

- 18-month warranty with full technical support across Ukraine

- Affordable price from the manufacturer — order directly and save

- Compliance with European standards (ISO, CE) — trusted in 18 export countries

Automate the drying process — boost your production efficiency with industrial equipment from KONSORT!

Improving in the organization of production and management

Improving in the organization of production and management  Productivity increase up to 70%

Productivity increase up to 70%  Lower production costs

Lower production costs  Reduction in human-related risks

Reduction in human-related risks - Food industry

- Agro-processing

- Packaging and freezing complexes

- Production of fresh berries, fruits, and vegetables

- European design provides a professional look

- Increased load capacity

- Ability to work in rooms with high humidity, acidity and alkalinity (in aggressive environments)