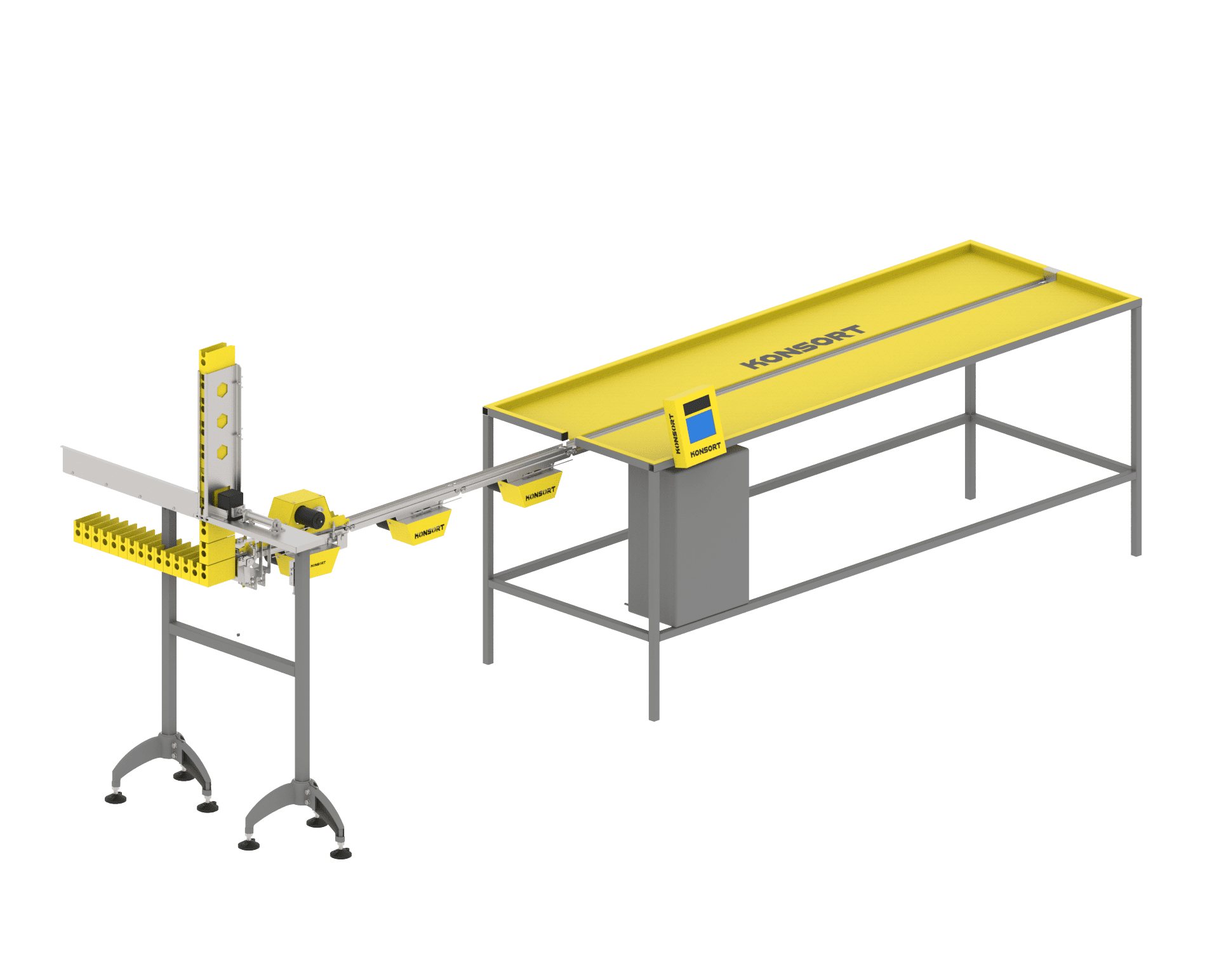

Sticker counting line

Order Stick Counting Line from the Manufacturer (Ukraine)

Description:

The Stick Counting Line is a modern technological solution for automating the processes of stick packaging and transportation. It is specifically designed for companies aiming to automate manual operations, improve dosing accuracy, and optimize production workflows. The system enables efficient transportation, batch forming, product alignment, distribution into filling molds, and delivery to the packaging area.

Components:

-

Stainless steel table

-

Positioning conveyor

-

Conveyor for information reading and queue formation

-

Conveyor for packing the filling molds

-

Mechanism for distributing empty and filled molds

Advantages:

✅ Full process automation

✅ Stainless steel construction ensures compliance with sanitary standards

✅ Optimized workflow

✅ Durable and reliable structure

✅ Easy integration into existing packaging lines and compatibility with food industry equipment

Ordering the Stick Counting Line from KONSORT ensures reliability — we control quality at every stage and provide post-sale support.

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Pharmaceutical companies

- Packaging departments for portioned products

- Cosmetic manufacturing facilities

- Enterprises specializing in sugar and coffee production

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used