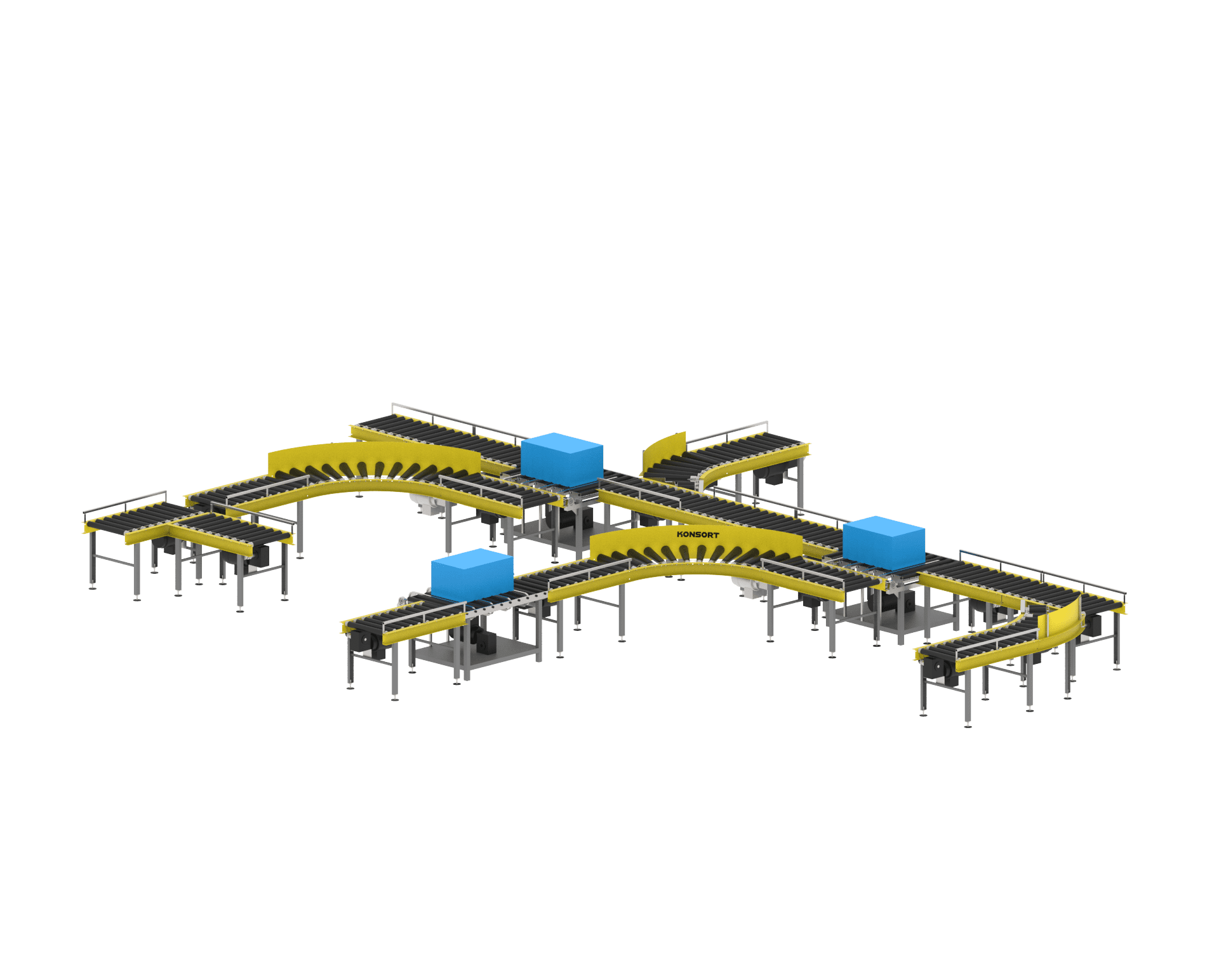

Furniture transportation line

Order a Furniture Product Transportation Line from the Manufacturer (Ukraine)

Description

The furniture product transportation line by Ukrainian manufacturer KONSORT is a modern solution for automating production processes, optimizing the supply and movement of furniture components and finished products. The equipment ensures continuous and precise product movement, reduces manual labor, and increases production efficiency.

Operating Principle and Components:

The line consists of 5 gravity roller conveyors and a ball transfer table. Using the gravity conveyors, the operator can easily move large furniture components, which travel smoothly thanks to 32 mm diameter rollers made of structural steel and equipped with plastic bearings.

The ball transfer table enables the operator to rotate the workpiece in the desired direction. The table is equipped with 230 ball transfer units, allowing 360˚ rotation of the transported object. The table frame is made from 60×30×2 mm profile tubing.

Why choose a KONSORT furniture transportation line:

✅ Over 18 years of experience in conveyor system manufacturing

✅ In-house production in Ukraine — quality control at every stage

✅ Custom manufacturing tailored to your dimensions and operating conditions

✅ Nationwide delivery and fast installation

✅ Technical support and professional consultations

Make your business more efficient today — order the furniture product transportation line from KONSORT. Our specialists will help you choose the optimal configuration, and delivery is available throughout Ukraine!

Improving in the organization of production and management by 50%

Improving in the organization of production and management by 50%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 30%

Lower production costs by 30%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - or automation of furniture parts feeding to subsequent stages of the production cycle

- For manufacturers of case furniture

- For transportation of woodworking industry products

- Stable transportation speed without delays or downtime

- Gentle handling of furniture blanks and finished products

- Possibility of adaptation to your production specifics

- European components