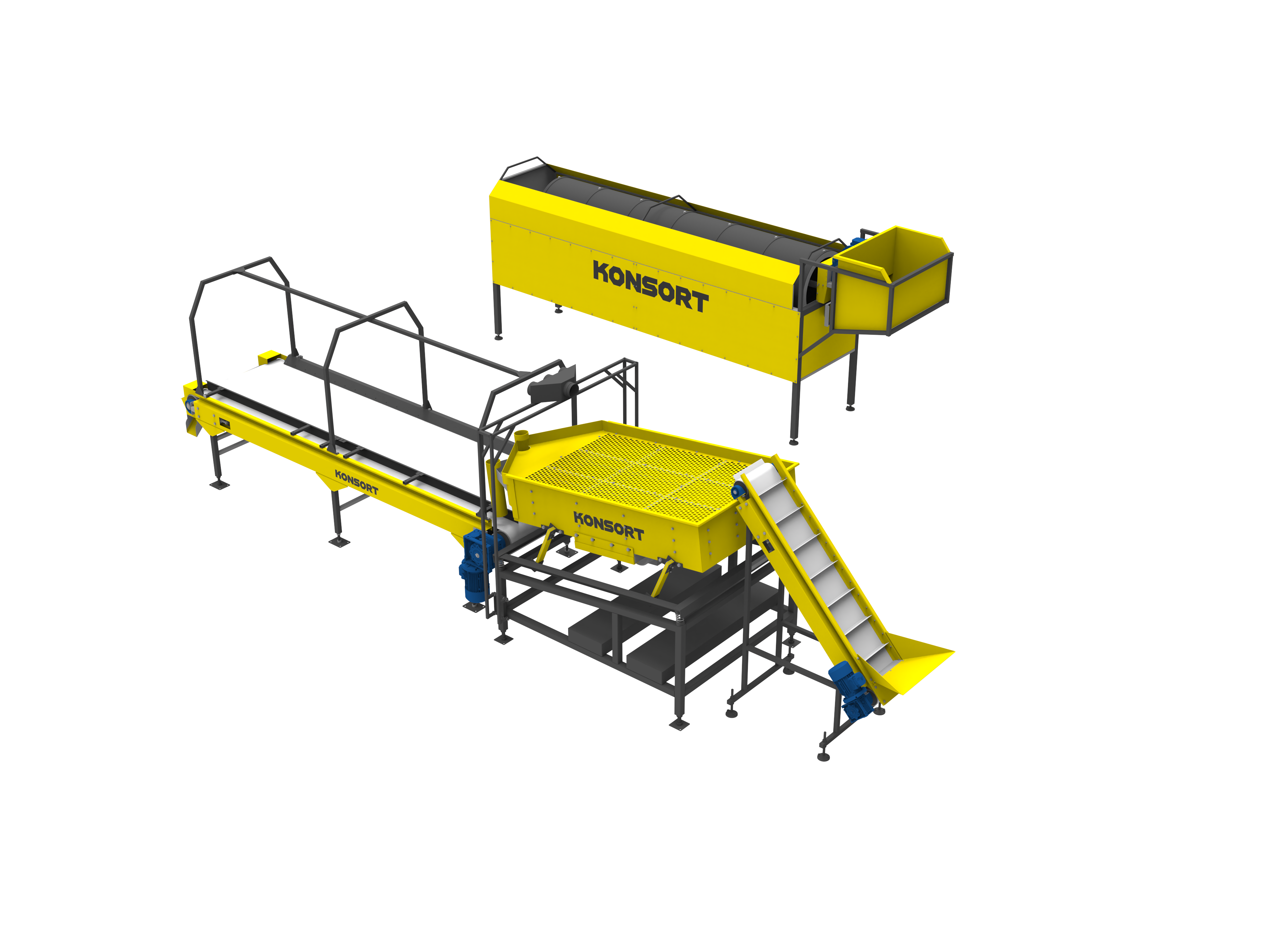

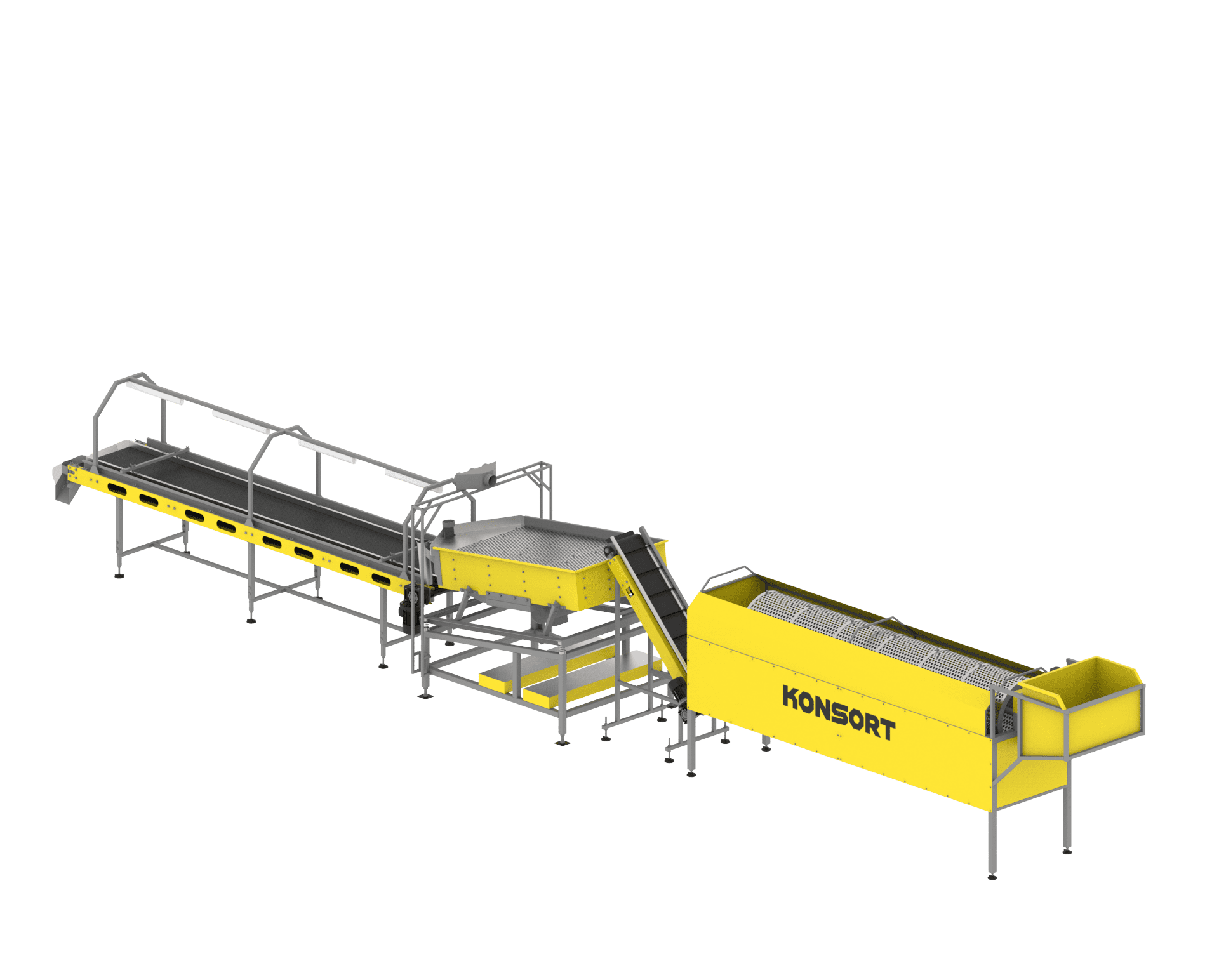

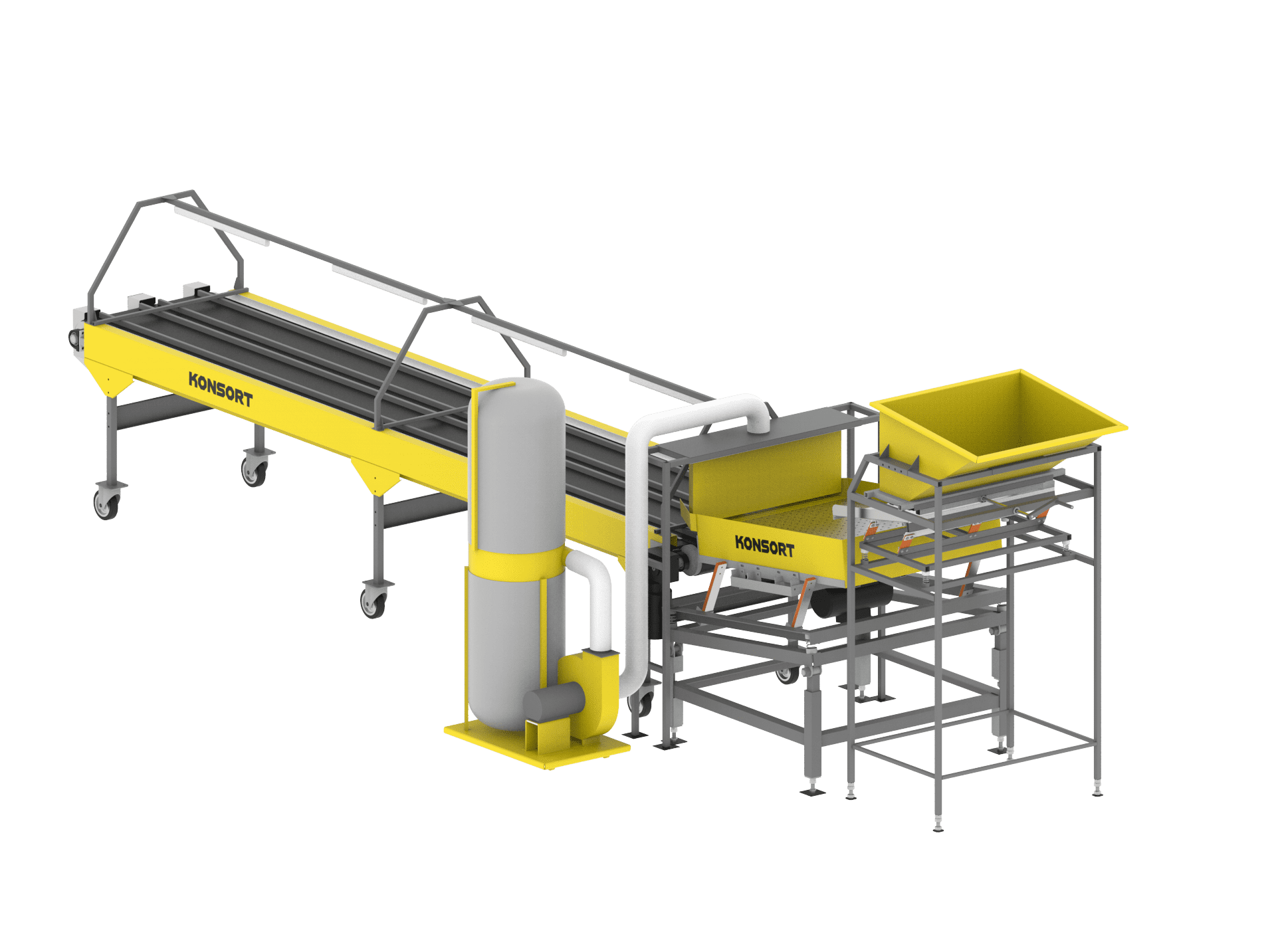

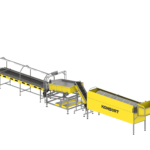

Line for processing nuts

Order a nut processing conveyor line from the manufacturer (Ukraine)

Description

The nut processing line is a modern industrial solution from the Ukrainian manufacturer KONSORT, designed for efficient, automated, and safe processing, sorting, and feeding of nuts. The equipment is specifically developed for food industry enterprises working with walnut kernels, hazelnuts, almonds, or peanuts.

The system automates the key stages of processing — from cleaning and calibration to transportation and packaging of products. This is an ideal solution for packaging lines where maintaining product integrity and quality is essential.

Advantages:

✅ High processing quality — minimizing raw material losses while maximizing productivity

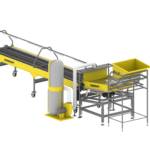

✅ Individual approach — designed according to the customer’s specific requirements

✅ Integration capability with other conveying, sorting, feeding, or packaging systems

Place your order for the nut processing line directly with the manufacturer! We will help you choose the solution that matches your production capacity

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower labour costs up to 30%

Lower labour costs up to 30%  Reduction in human-related risks up to 30%

Reduction in human-related risks up to 30% - Snack food production

- Nut processing, grading, and packaging enterprises

- Agro-processing enterprises

- European design provides a professional and clean look

- The equipment is designed in accordance with all the rules and regulations put forward to the food industry equipment

- There is possibility to complete the line with extra components if necessary

- Production process is automated