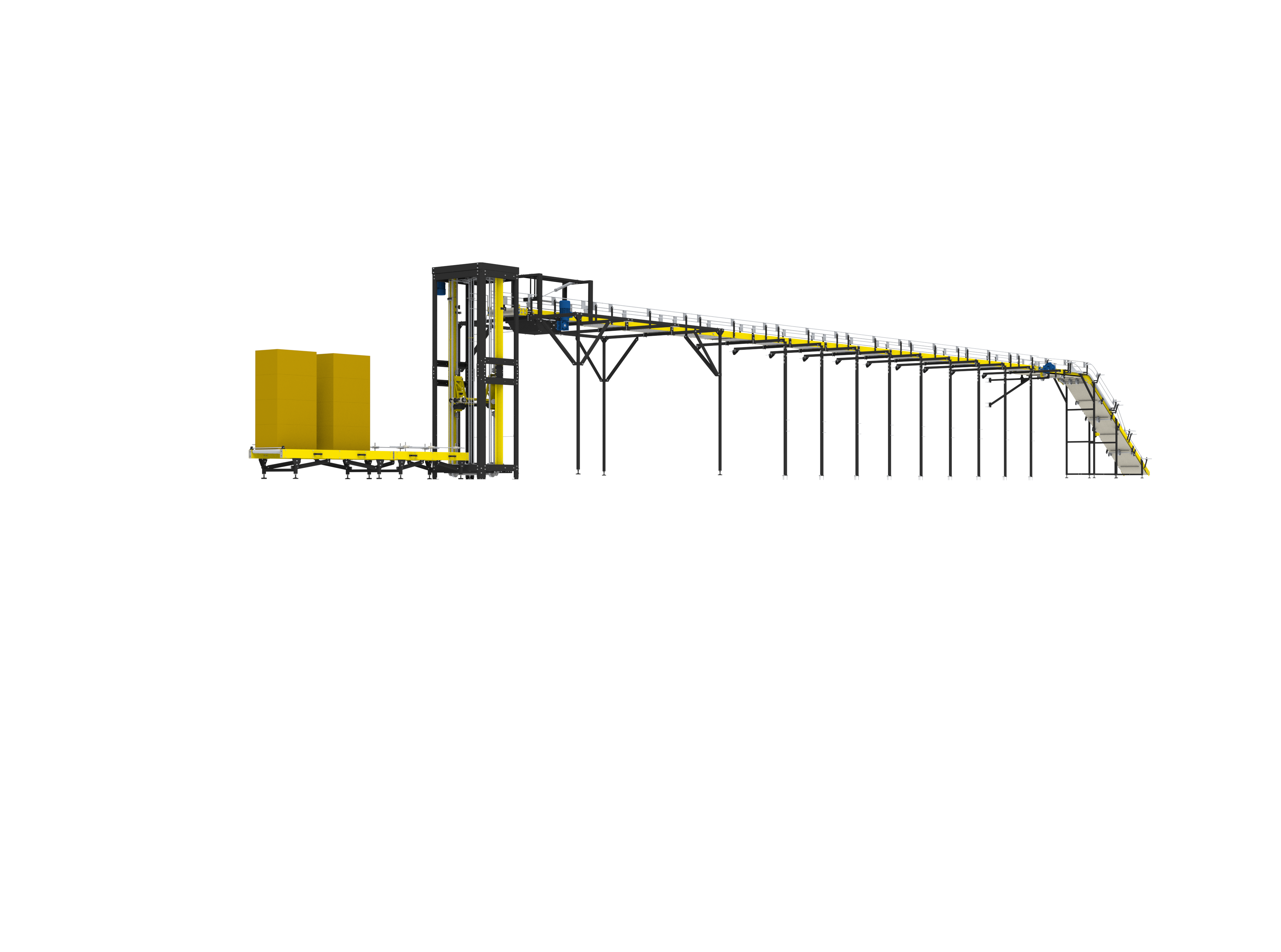

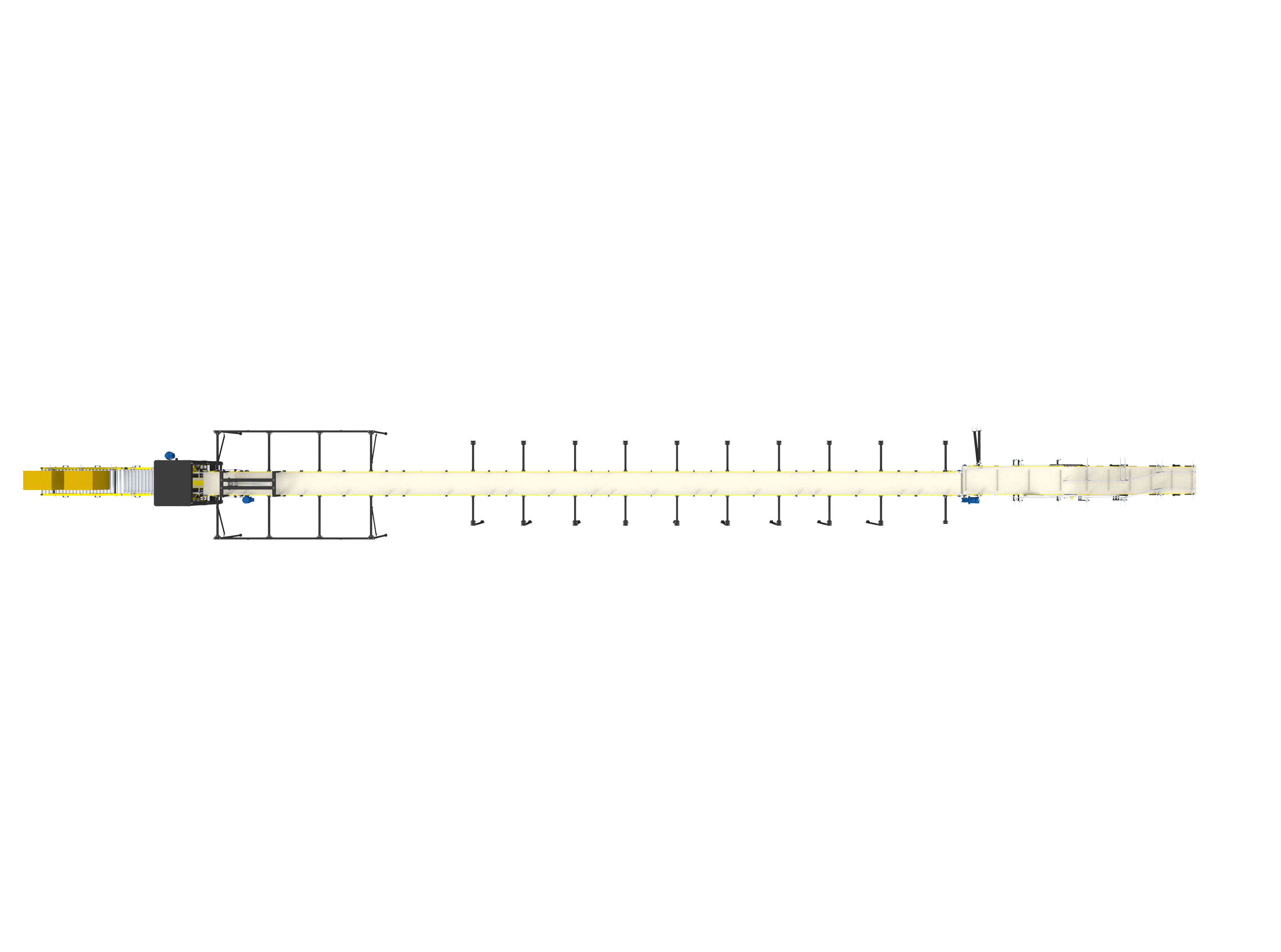

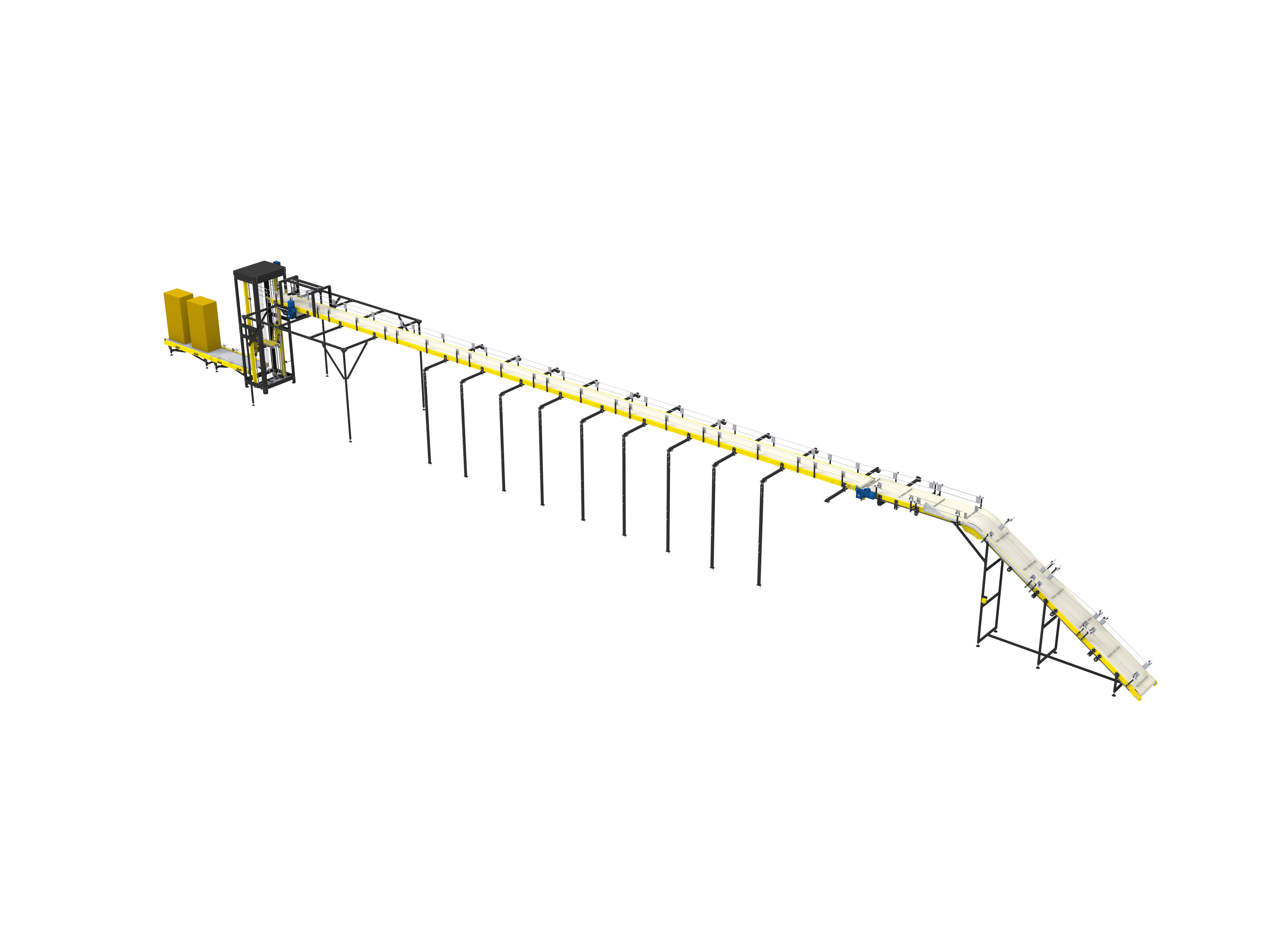

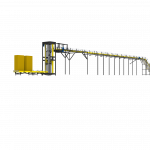

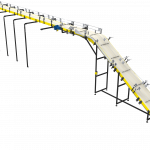

Conveyor line for transporting boxes

Order a Box Conveyor Line Directly from the Manufacturer (Ukraine)

Description

The box conveyor line is a reliable solution for companies aiming to automate processes such as sorting, packing, and product transportation. The equipment is ideal for the food industry, logistics centers, production facilities, and warehouses. Thanks to its modular design, the conveyor line can be easily integrated into existing systems and tailored to specific technical requirements.

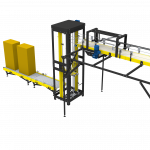

This system ensures smooth transport of finished products from the packaging area to the warehouse, as well as automatic stacking of boxes (up to 10 units) for convenient pallet loading.

Components:

-

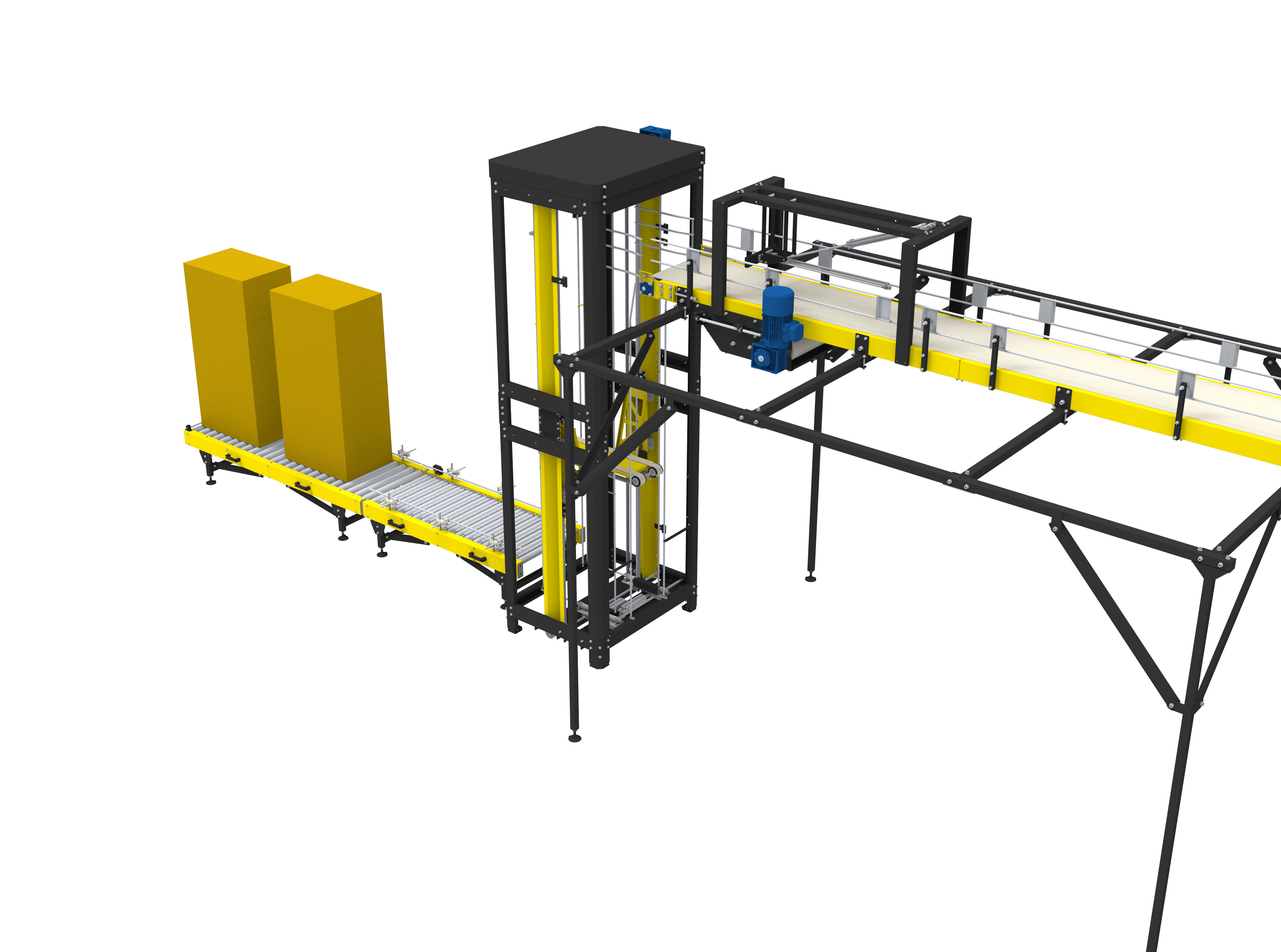

L-shaped conveyor with a box-flipping function for correct positioning

-

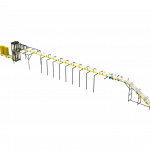

Horizontal conveyor

-

Vertical lifting conveyor

-

Driven and non-driven roller conveyor

Advantages:

✅ Automation of transport reduces the need for manual labor and accelerates product handling.

✅ Compact box stacking allows for more efficient use of warehouse space.

✅ Gentle handling systems minimize the risk of mechanical damage to the goods.

✅ Increased process speed shortens the overall production cycle.

✅ Expandable system with the possibility to integrate additional conveyor modules for higher levels of automation.

Order your box conveyor system at a competitive price directly from the manufacturer in Ukraine!

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Confectionery production

- Food industry

- Warehouse logistics

- Wholesale retail

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Automation of the production process