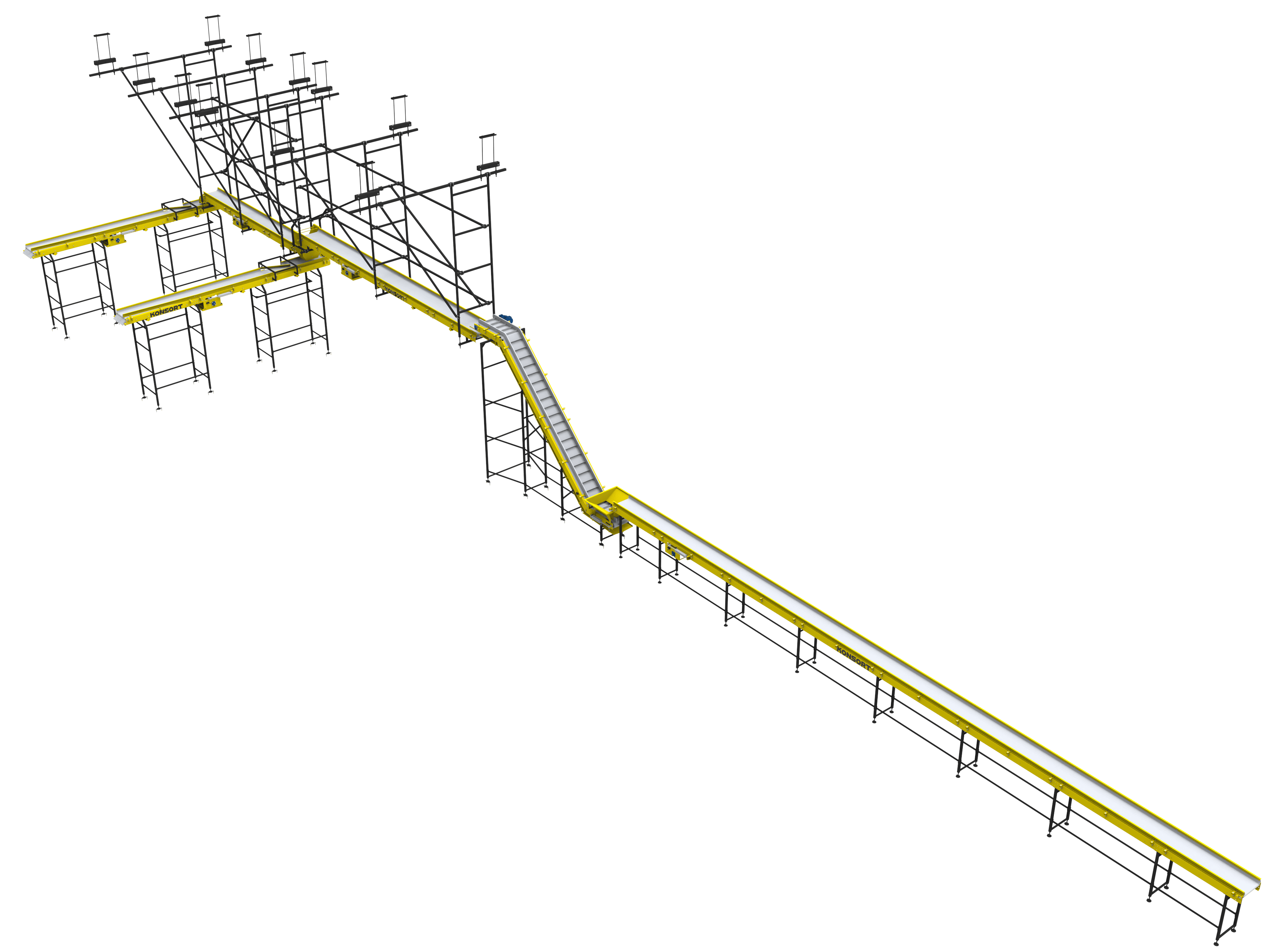

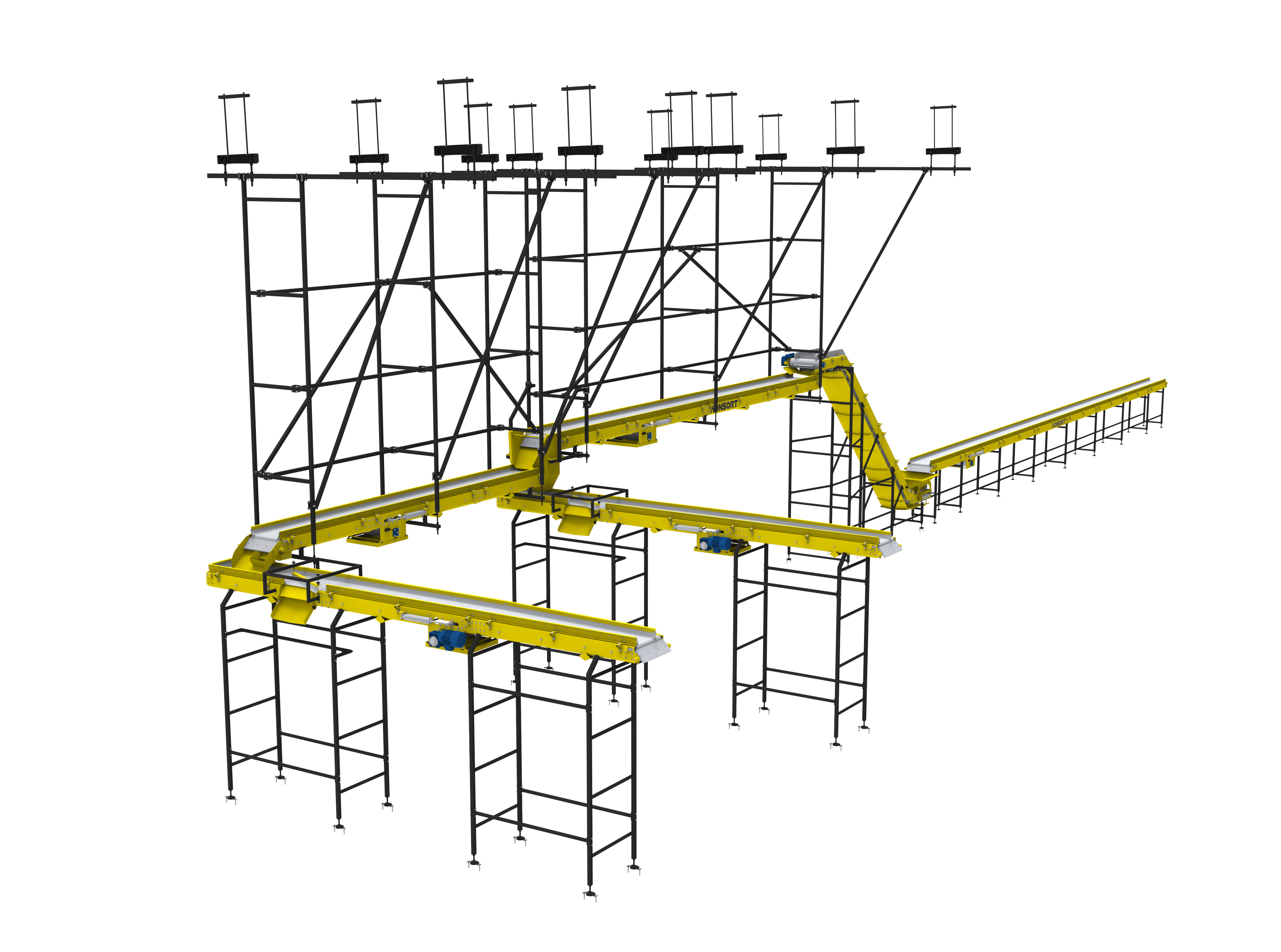

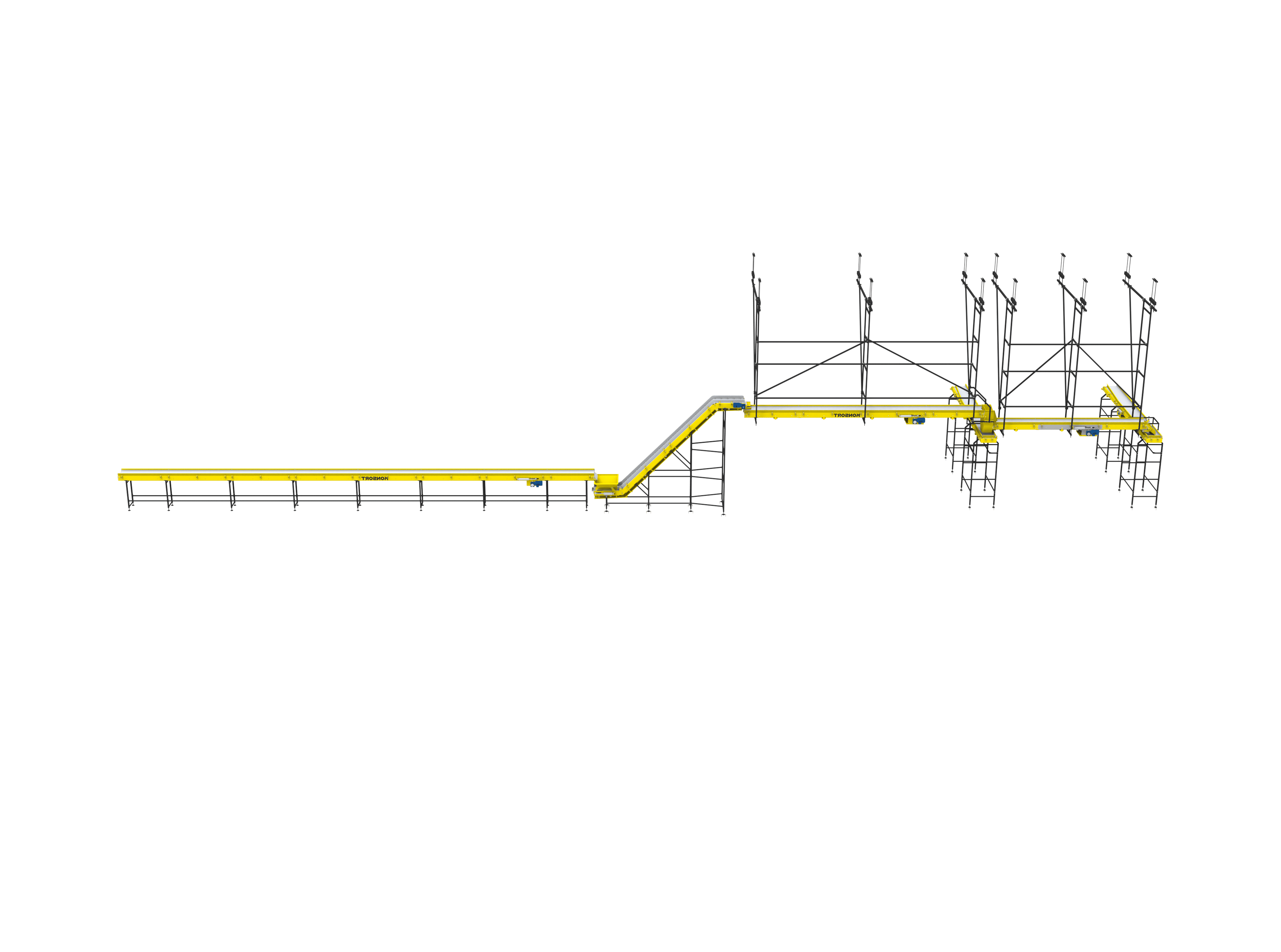

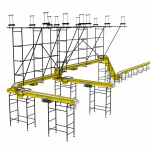

Wafer-based confectionery conveyor line

Wafer-based confectionery conveyor line — high-efficiency solution for production sutomation

The wafer-based confectionery conveyor line from KONSORT is a specialized industrial system designed for the automated transfer of crushed wafer sheets from the gas oven to the candy forming station. Engineered to meet the demands of modern manufacturing, this solution ensures high throughput, precision handling, and continuous, reliable operation.

Application and functionality

This conveyor line is tailored for confectionery manufacturers producing candies, bars, and other sweets based on wafer components. It offers:

✅ Continuous and controlled delivery of wafer crumbs to the forming unit

✅ Consistent product quality through precise dosing and uniform crushing

✅ Reduced manual intervention, minimizing human error

✅ Streamlined production flow with minimized transition time between processing stages

Key advantages of the KONSORT conveyor system

- Optimized for wafer crumb handling — a specially designed belt and guiding system ensures smooth, gentle transport without sticking or material loss.

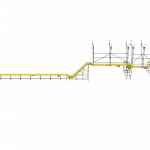

- Modular architecture — allows for easy customization of conveyor length, width, and height based on layout or product requirements.

- Hygienic design — all product-contact surfaces are made of food-grade AISI 304 stainless steel.

- Reliable under continuous load — industrial-grade drive systems and precision bearing assemblies guarantee stable 24/7 operation.

- Easy maintenance — fast access to core components, removable guides, and quick-clean features reduce downtime during sanitation.

Why choose KONSORT’s wafer conveyorline?

✅ Up to 18-month manufacturer warranty

✅ Over 7,000 implemented projects across Ukraine and abroad

✅ Exported to more than 18 countries worldwide

✅ Full-service support available across all regions of Ukraine

Order your wafer-based confectionery conveyor line from KONSORT today! Ensure the stable operation of your production — call us or submit a request on our website.

Improving in the organization of production and management by 50%

Improving in the organization of production and management by 50%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - For transporting products at confectionery factories

- For wafer product manufacturing For flour and cereal production enterprises

- For flour and cereal production enterprises

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Production process is automated

- There is possibility to install sound and light alarms