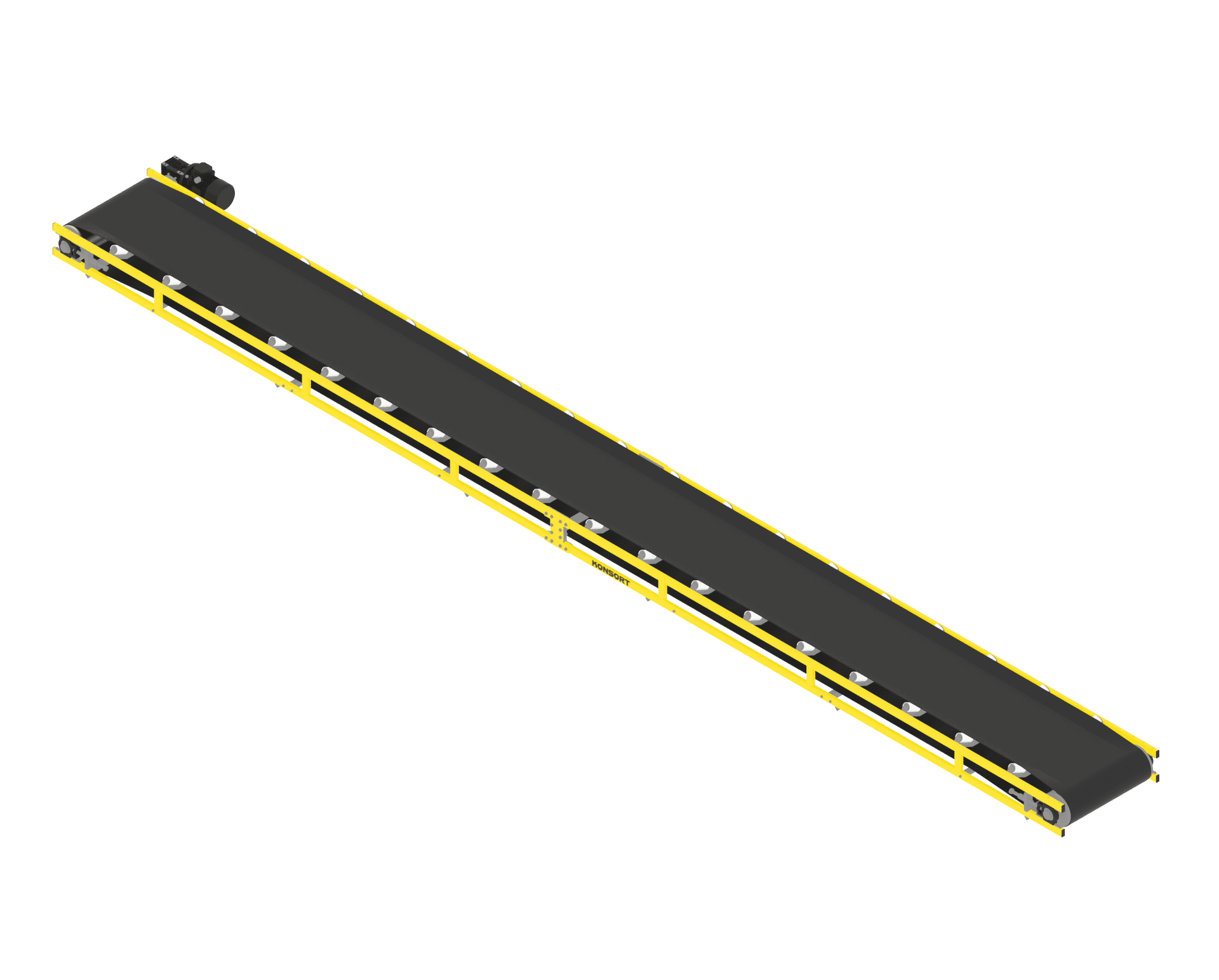

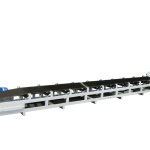

Troughed belt conveyor (universal heavy-duty conveyor)

Troughed belt conveyor (universal heavy-duty conveyor) — a reliable solution for automated material handling

The troughed belt conveyor from Ukrainian manufacturer KONSORT is a highly efficient and versatile industrial solution designed for horizontal transportation of unit loads and bulk materials, as well as inclined conveying when overcoming height differences. This type of conveyor is ideal for production automation, logistics process optimization, and boosting enterprise productivity.

Widely used across the food and non-food industries, this conveyor handles heavy bulk materials, large-sized goods, and packaged products with ease. Its robust construction ensures reliable performance even under intensive operation and prolonged workloads.

Operating principle of the troughed belt conveyor

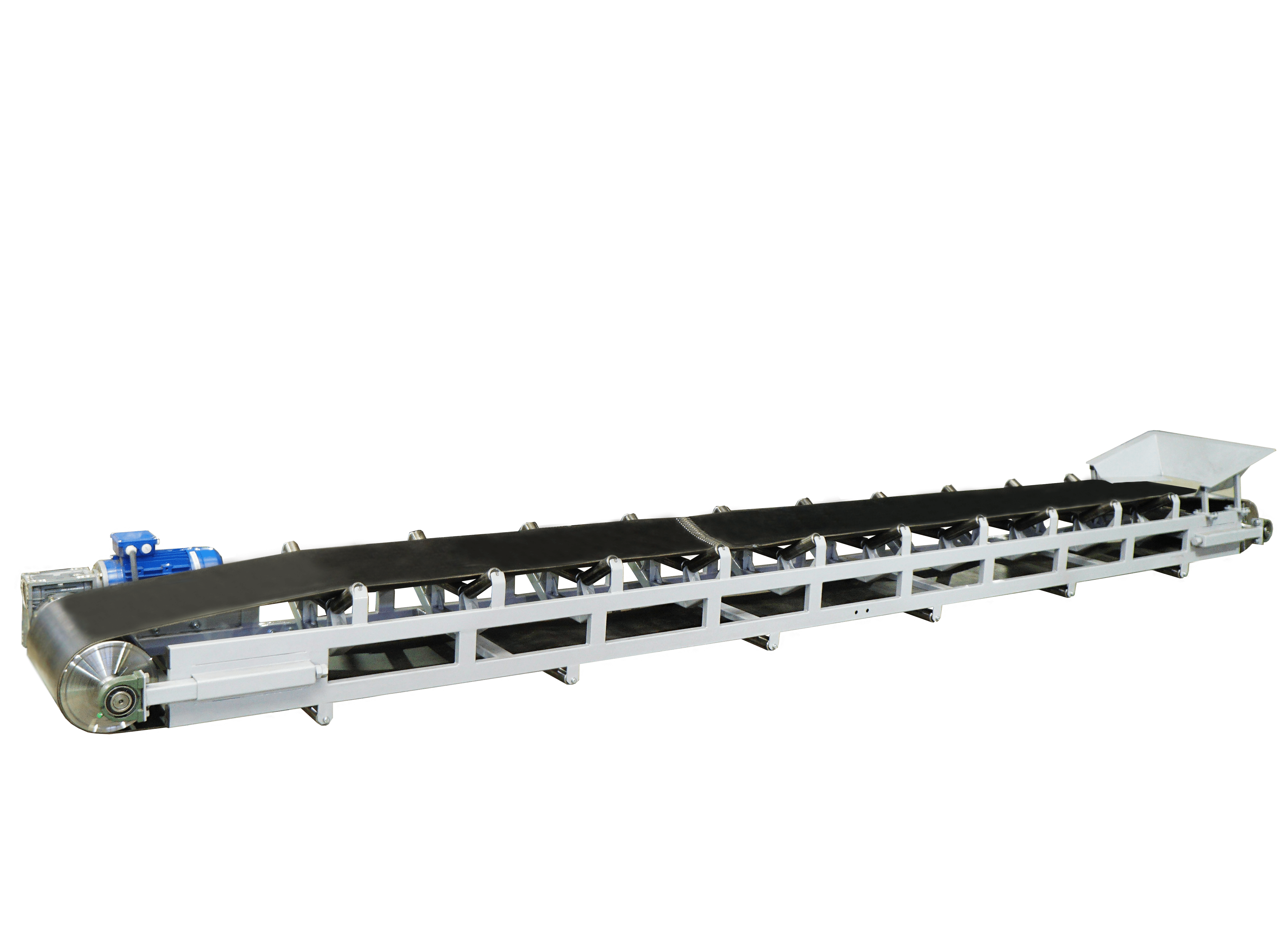

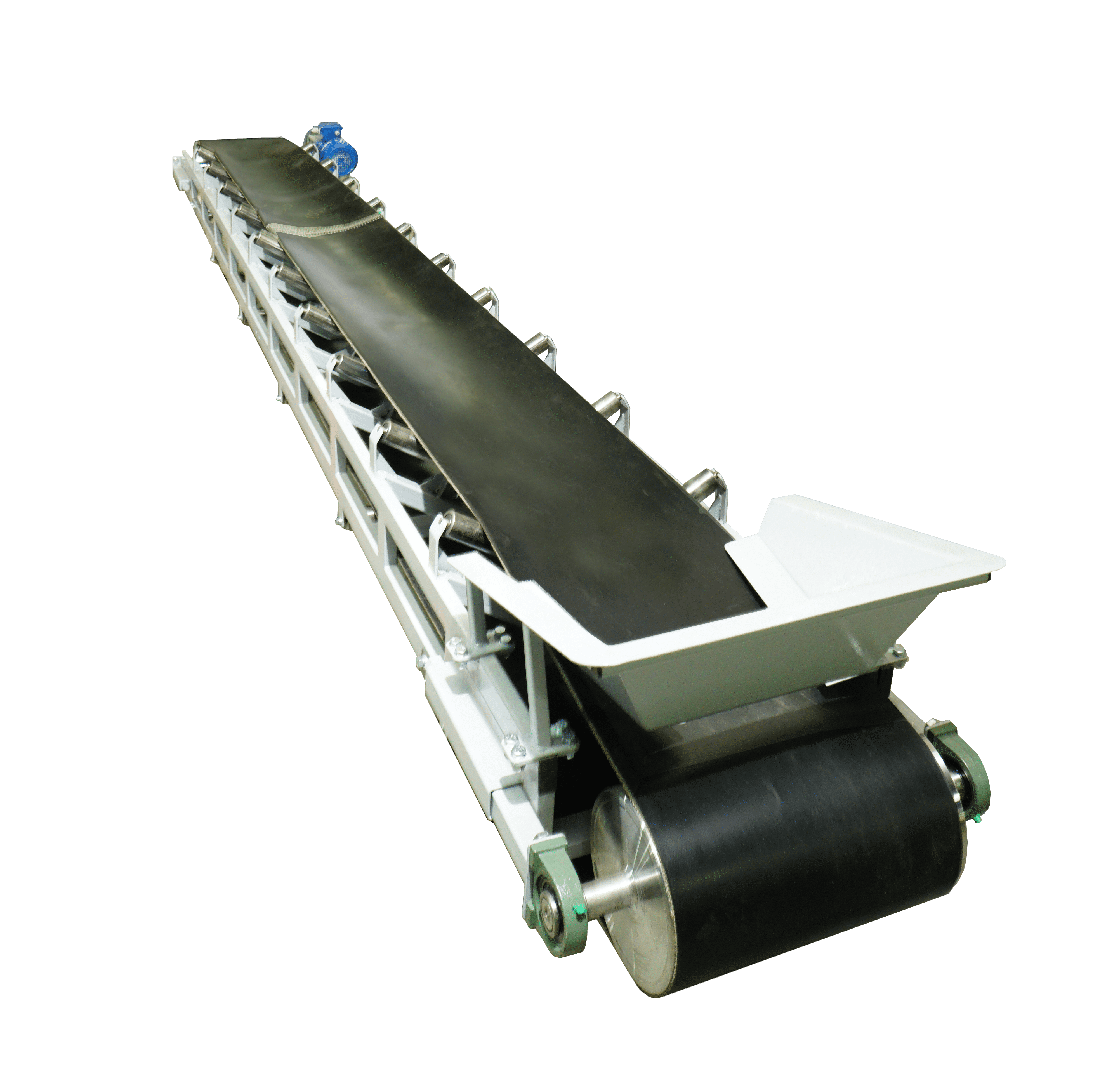

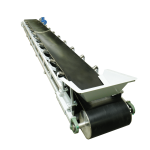

The conveyor operates on the principle of continuous belt movement supported by trough-shaped idlers. This configuration forms a trough-like belt profile, allowing secure material containment along the entire conveying route — even when operating on inclines or across height changes.

- Material is loaded onto the belt at the upper or lower end of the conveyor

- The trough-shaped profile prevents spillage of bulk materials and shifting of unit loads

- Continuous motion ensures smooth and consistent conveying without jerks

- Easily integrates into production lines and can function as standalone equipment or as part of a complex material handling system

Advantages of using a troughed belt conveyor

- High versatility — suitable for food and non-food products, bulk and unit loads

- Reliable inclined conveying — trough-shaped belt securely holds materials on steep sections

- Optimized use of production space — enables operation at multiple levels, reducing the need for additional lifting equipment

- Smooth and safe product handling — minimizes risk of material damage or loss

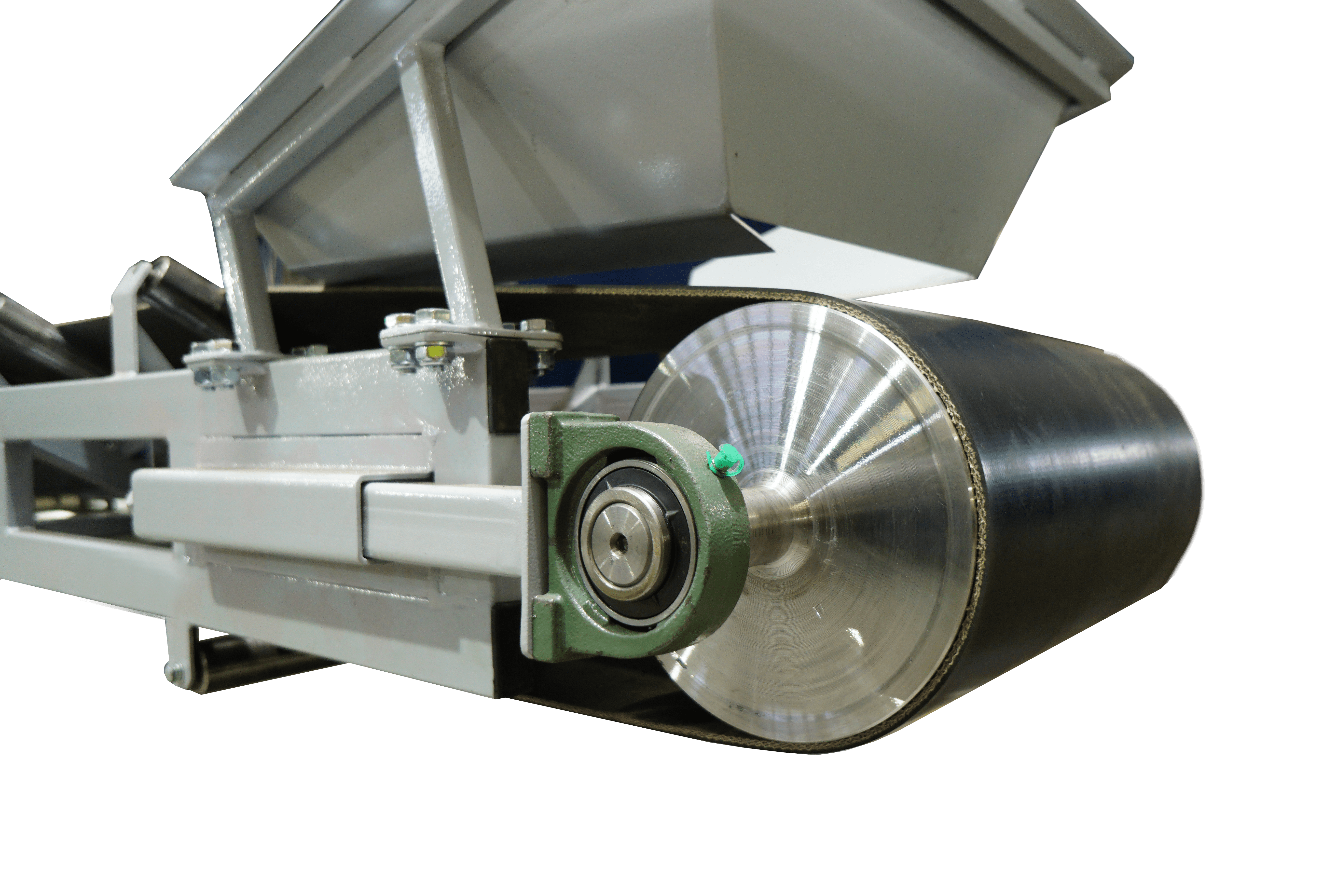

- Long service life and durability — designed for continuous operation under heavy loads

Why choose a troughed belt conveyor from KONSORT

✅ In-house manufacturing in Ukraine — quality control at every production stage

✅ Custom engineering — designed and built to match your specific production needs

✅ 18+ years of expertise in conveyor system manufacturing

✅ Direct-from-manufacturer pricing — no unnecessary mark-ups

✅ Service and support — assistance with installation and setup

How to order a troughed belt conveyor

- Submit a request on our website or contact our sales manager

- Define the parameters and technical requirements for your production process

- Receive a tailored quotation with pricing and lead times

- We will deliver and, if required, install your equipment

By choosing a troughed belt conveyor from KONSORT, you are investing in higher efficiency, improved automation, and reliable heavy-duty material handling. Order your conveyor today — get a professional consultation and the best manufacturer price!

Improving in the organization of production and management

Improving in the organization of production and management  Productivity increase up to 70%

Productivity increase up to 70%  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks - For transporting grains, flour, sugar, cereals, seeds, animal feed

- For transporting sand, gravel, cement, crushed stone

- For moving packaged and piece goods to different levels

- European design provides a professional look

- All conveyor mechanisms are equipped with external bearing units, which allows lubricate bearing without disassembling the equipment. This reduces maintenance time

- Durable powder coating

- Adjustable belt speed