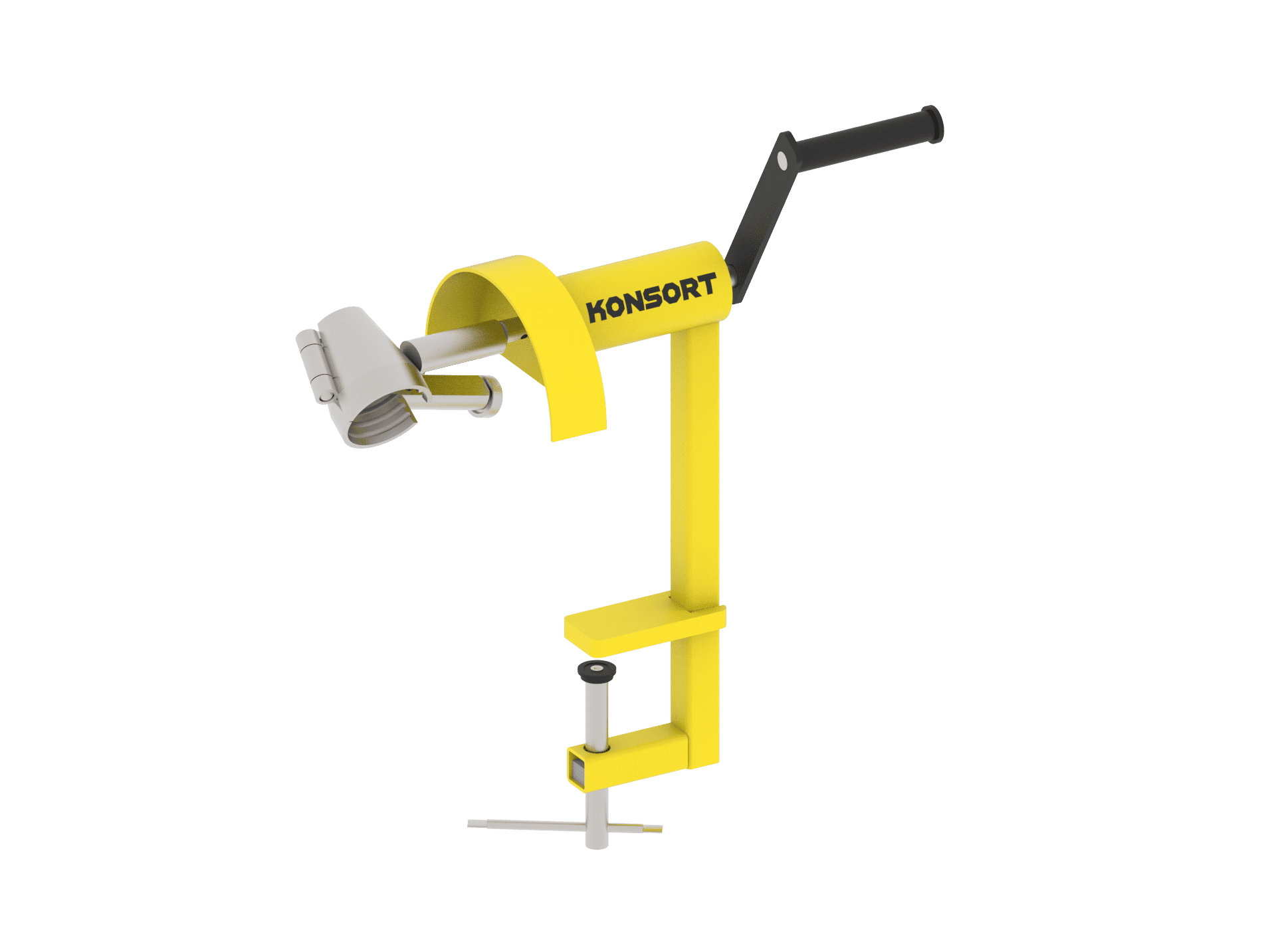

Nutcracker

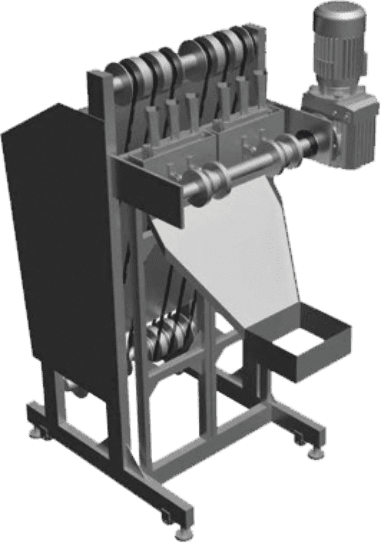

The Nut Cracking Machine from KONSORT is a high-performance industrial device for shelling nuts, designed for food processing companies, agricultural enterprises, and production lines. The equipment enables fast and accurate cracking of walnuts, hazelnuts, almonds, and other hard-shell nuts without damaging the kernel.

Application and Benefits

The nut cracker is used for automated shell cracking, which significantly reduces manual labor, minimizes product loss, and increases processing speed.

Key advantages:

-

High productivity – fast processing of large nut volumes

-

Adjustable settings – optimized for different shell sizes and hardness levels

-

Low product loss – kernels remain intact

-

Durable construction – made of high-strength steel

-

Safe operation – integrated operator safety features

Operating Principle

The machine works by mechanically compressing the nut between two surfaces, one of which is movable. The feeding system ensures an even supply of nuts into the working area, where they are held in place and subjected to controlled pressure.

Thanks to adjustable compression force and precise calibration, the shell cracks while the kernel remains undamaged. The processed nuts can then be automatically forwarded for sorting or further processing.

This system allows for universal handling of nuts of different sizes and hardness levels, without the need to reconfigure the equipment.

Why Buy the Nut Cracking Machine from KONSORT?

KONSORT is a Ukrainian manufacturer with over 15 years of experience in industrial equipment. We design and implement automation solutions for the food and agro-industrial sectors.

When buying directly from the manufacturer, you receive:

-

Certified quality and technical compliance

-

Custom production tailored to your requirements

-

Technical support and consultation

-

Competitive pricing – no intermediaries

Don’t postpone modernization! Order your nut cracking machine today to automate nut processing, save time, and reduce production costs.

Call us or fill out the form on the website — we will help you choose the right model, place an order, and launch the machine at your facility.

Preservation of product integrity and its quality

Preservation of product integrity and its quality  Productivity increase up to 70 %

Productivity increase up to 70 %  Workforce optimization up to 50%

Workforce optimization up to 50%  Reduction in human-related risks

Reduction in human-related risks - Food industry enterprises

- Farming enterprises

- Processing workshops and cooperatives

- Berry, nut, mushroom, and vegetable processing enterprises

- European design

- Manufacturing process automation

- Profit increase by 70%

- Easy to use and operate