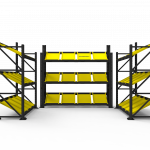

Conveyor cargo sorting system PUT-TO-LIGHT

The PUT-TO-LIGHT conveyor sorting system is an innovative and high-tech solution for automating sorting processes in warehouses and the food industry. This system combines the efficiency of conveyor transportation with intuitive visual control using lighting, significantly reducing sorting time, minimizing operator errors, and increasing productivity.

Advantages of the PUT-TO-LIGHT system from KONSORT:

-

High accuracy and sorting speed — the system can process up to 3600 parcels per hour, ensuring fast and error-free cargo distribution.

-

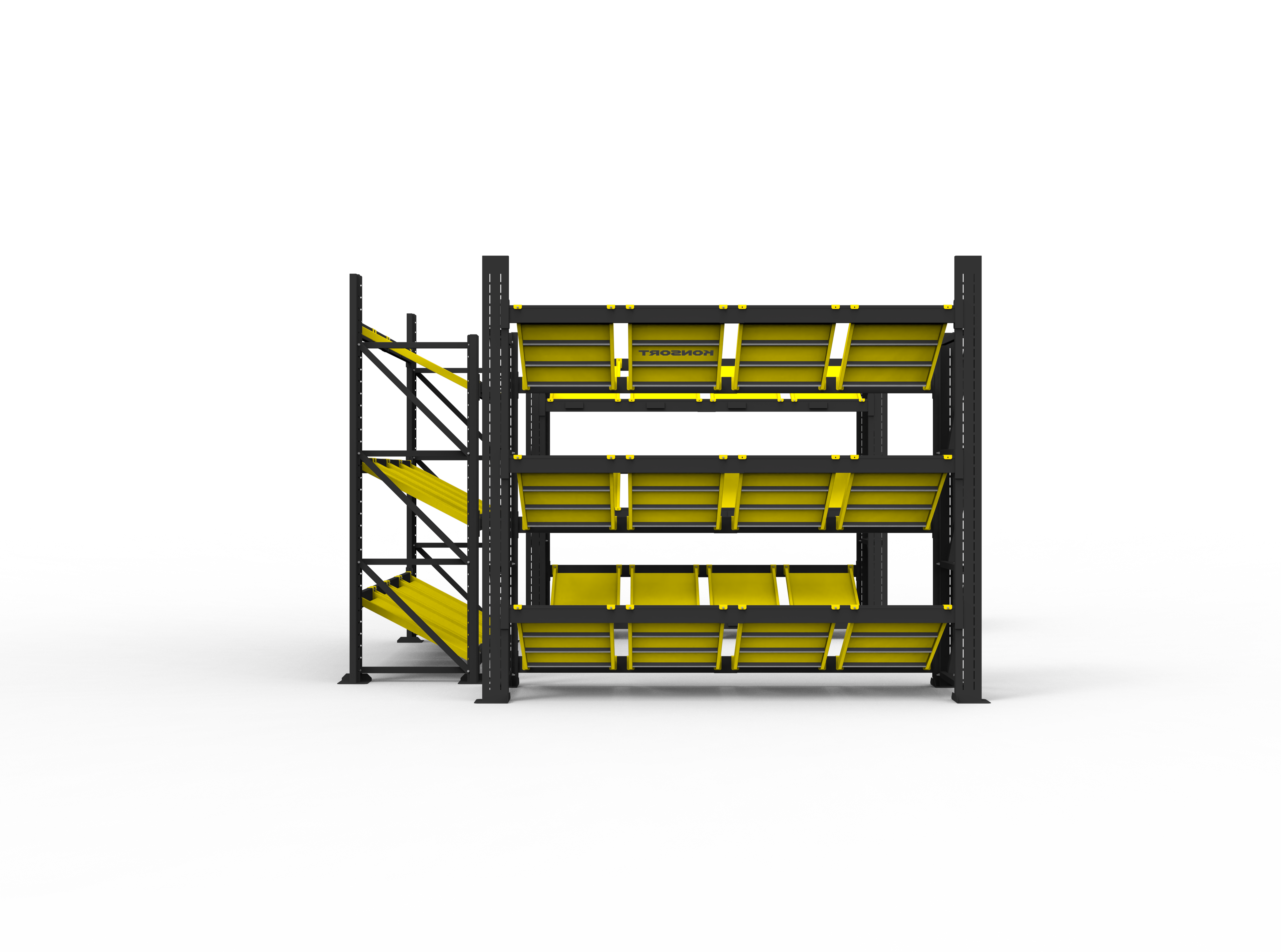

Intuitive operation — lighting in sorting bins notifies operators of the correct location for each item, greatly reducing the risk of human error.

-

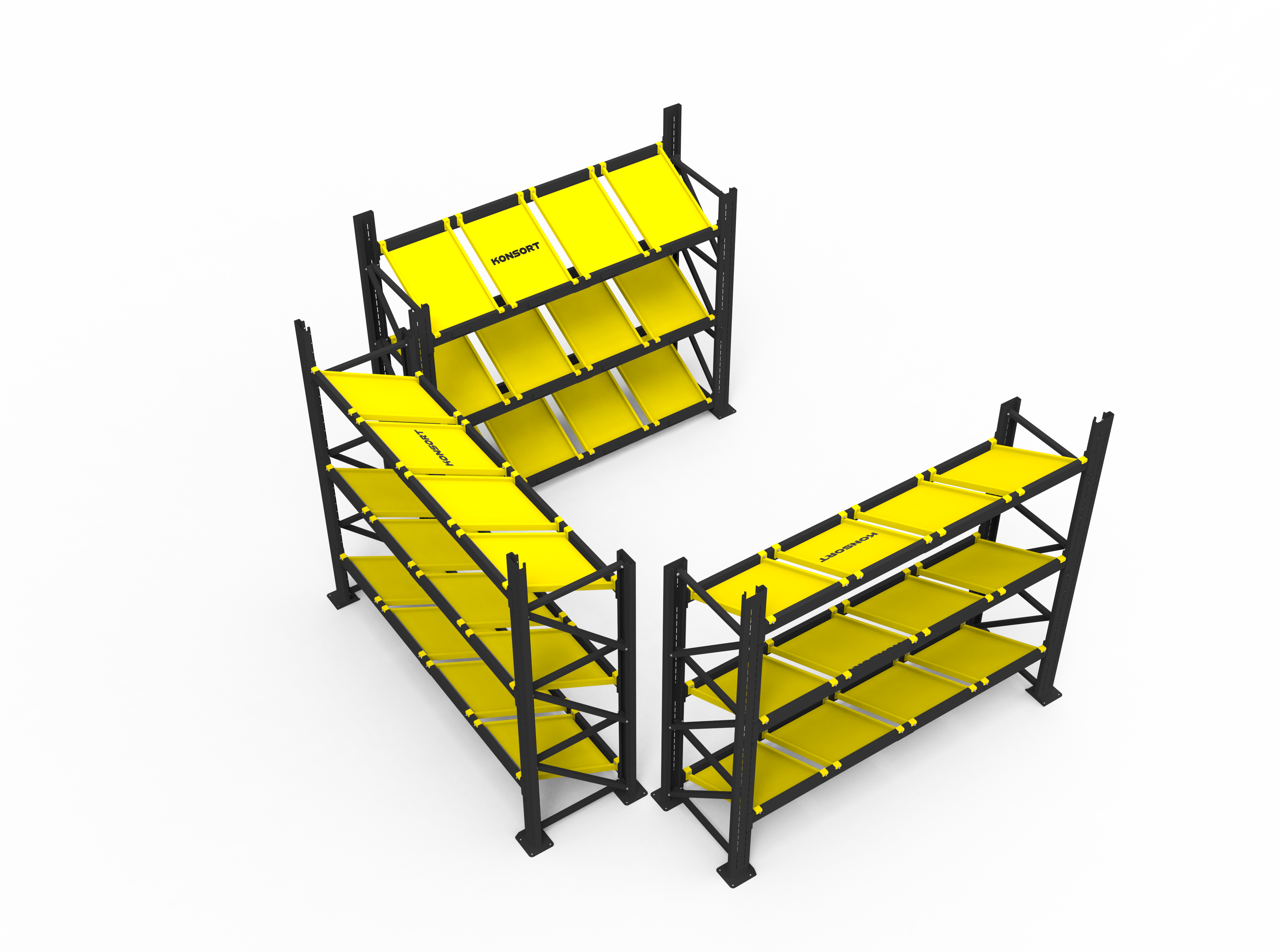

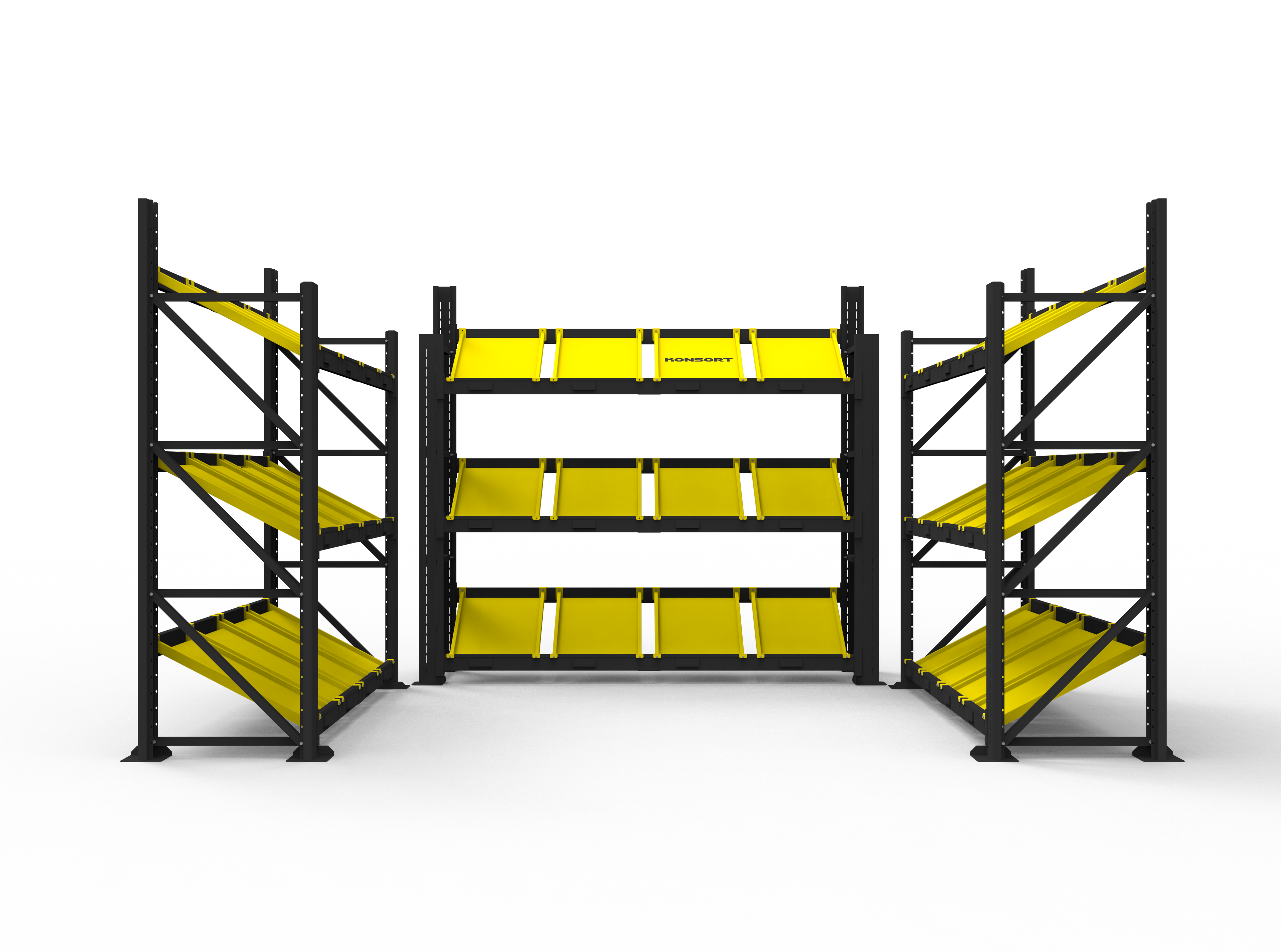

Flexibility and scalability — the number of sorting bins can be expanded and adapted to various production or warehouse conditions.

-

Integration with existing WMS — full compatibility with warehouse management systems for synchronized operation and process optimization.

-

Reliability and durability — all components are made of high-quality materials certified by ISO and CE, guaranteeing long service life.

Why buy the PUT-TO-LIGHT sorting conveyor system from KONSORT?

-

Direct from manufacturer — quality assurance and competitive prices without intermediaries.

-

Individual approach — system development and configuration tailored to your business needs.

-

Delivery across Ukraine — fast logistics and service support.

-

Warranty and post-warranty service.

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Confectionery production

- Food industry

- Warehouse logistics

- Wholesale retail

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used