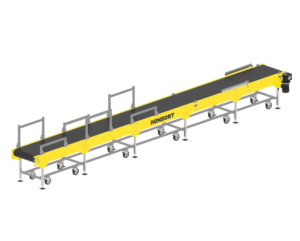

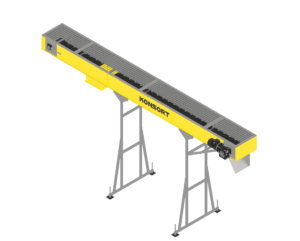

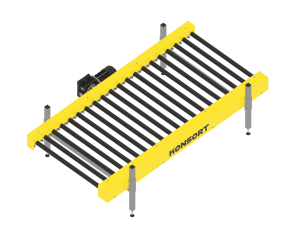

03. Conveyors for Moving Heavy, Oversized, and Bulk Materials

Due to the growth in production volumes, “Budservis-Eco”, a company specializing in the manufacturing and wholesale distribution of construction materials (gravel, sand, cement, concrete blocks), faced the need to enhance the efficiency of transporting products.